DAVENPORT MACHINE has developed multispindle lathes to automate and rapidly produce large quantities of parts, always prioritizing customer satisfaction. Today, the implementation of automation technologies has made these machines highly efficient for large production cycles. Furthermore, Davenport continues to innovate machines that are faster, more sustainable, and require less training and investment.

Davenport's multispindle machines are specialized and automated lathes designed to meet most production needs. Davenport offers various models of lathes: Davenport HP, a high-precision machine to enhance efficiency and production; Davenport model B, one of the fastest and most cost-effective machines for high-volume component production; and recently, Davenport introduced the new multispindle HYBRID machine, which combines mechanical versatility of multispindle machines with the precision of CNC machines, ensuring greater productivity.

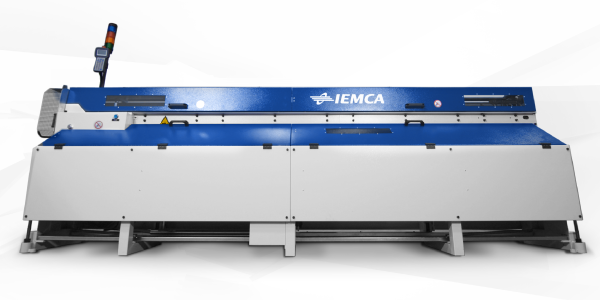

IEMCA has developed the multispindle bar loader NEXT 25 for the American market in collaboration with Davenport Inc., exclusively for installation on Davenport Hybrid Machines. The NEXT 25 for Davenport replaces the traditional bar bundle and features 5 polyurethane guide channels to feed the 5 spindles characteristic of Davenport lathes. The NEXT 25 bar loader also provides a bar magazine that allows for side loading and automatic loading operations for unmanned production.