Choosing an advanced high-pressure system for a sliding headstock lathe requires a thorough technical analysis of the entire installation, which goes beyond considering basic parameters such as pressure and flow rate, and includes practical and operational aspects that directly impact overall efficiency.

Here are 5 key aspects to know and evaluate before purchasing a high-pressure system, in order to select a solution truly suited to the lathe and the production process.

1. Flexibility in Configuring Outlet Pressures

In many machining operations, it is necessary to manage tools that require different pressures within the same work cycle, or to provide low-pressure washing. A truly efficient high-pressure system must therefore allow for diversified outlet pressures.

The presence of dedicated reduction valves makes it easy to adjust the pressure to individual utilities, ensuring maximum operational flexibility.

2. Energy Efficiency

An increasingly relevant aspect in choosing an advanced high-pressure system is energy efficiency. The most advanced solutions are particularly attentive to energy consumption and designed to supply only the amount of fluid required by the lathe, avoiding waste and reducing heat generation.

Although they may require a higher initial investment, these systems significantly reduce consumption and operating costs, ensuring a rapid economic return and a positive impact on the overall sustainability of the plant.

3. Activation Times

An efficient high-pressure system must ensure that the coolant is immediately available, with no waiting time for circuit pressurization. If the required pressure is not reached instantly, the operator is forced to switch on the unit in advance or delay the start of machining, resulting in wasted time and energy.

The most advanced solutions guarantee the immediate availability of pressurized fluid, always ready for use when required by the machining cycle, reducing downtime and increasing overall efficiency.

4. Frequency and Complexity of Maintenance

The high-pressure system must be designed to minimize the frequency and complexity of maintenance operations. Several elements make a difference in terms of practicality and continuity.

The presence of two filtration stages, for example, prevents filter overload and extends service life—whereas single-stage solutions require more frequent interventions. In addition, the duplex configuration, with parallel filters and a bypass system, allows replacement without interrupting the filtration process.

The type of filter used also plays a significant role: cartridges with a large filtering surface improve system longevity, while self-cleaning solutions further reduce the frequency of interventions, though requiring more demanding maintenance cycles.

The inclusion of a dedicated filtered coolant tank inside the high-pressure unit simplifies operations and reduces maintenance needs compared to systems without a tank or with partial filtration.

Finally, fully sensor-equipped high-pressure systems autonomously monitor filter conditions and notify the operator panel when replacement or cleaning is required, eliminating manual checks and preventing unexpected downtime.

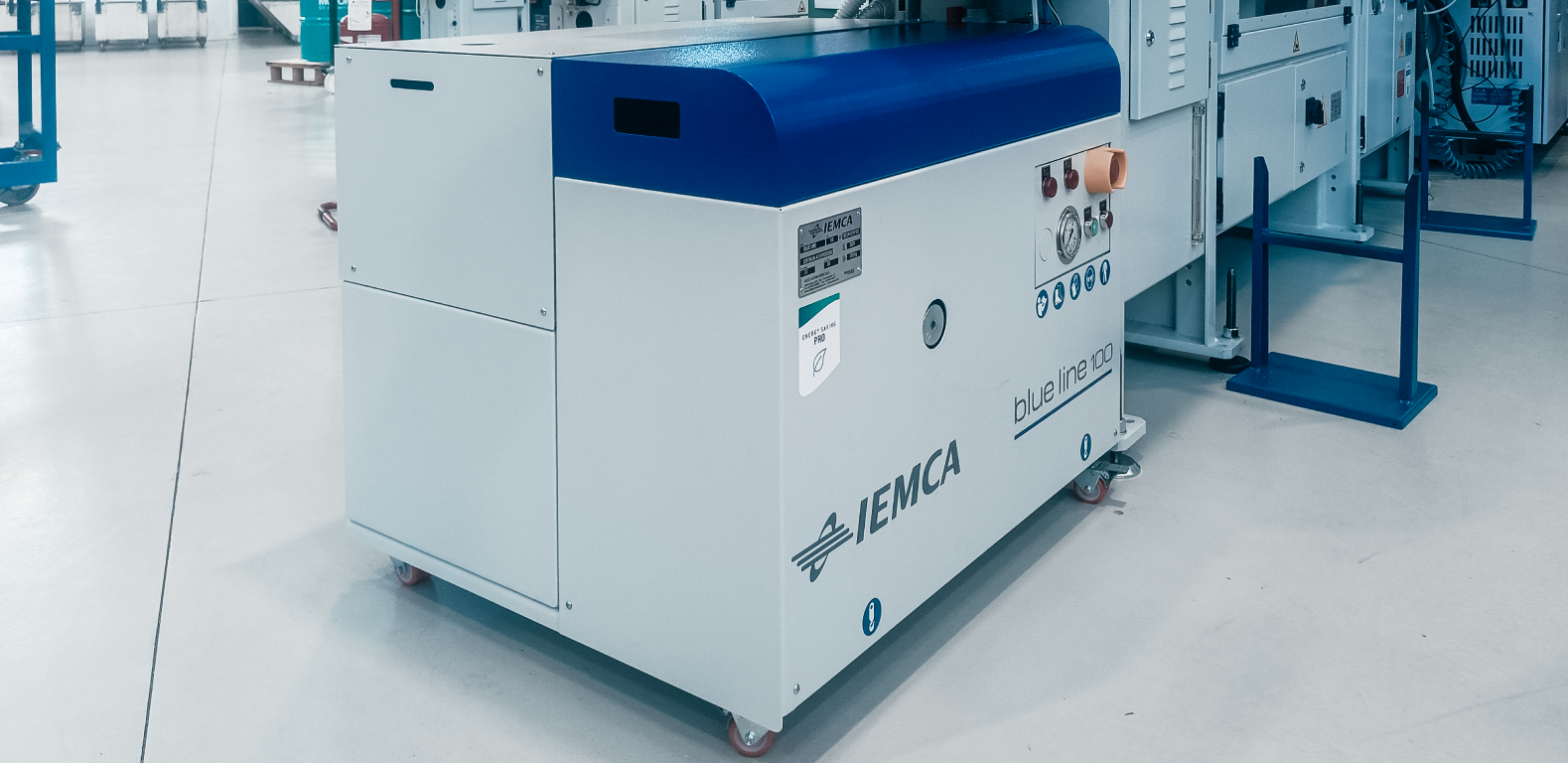

5. Space Requirements and Positioning in the Workshop

In addition to the overall footprint, it is essential to verify how much the high-pressure system allows for flexibility in defining the layout.

A compact and properly dimensioned unit can, for example, be installed under the bar feeder.

The possibility of positioning the unit without constraints in relation to the machine tool is an additional advantage. Advanced high-pressure solutions, equipped with a transfer pump and clean tank, can also be placed at a distance from the lathe, offering greater flexibility in organizing production space.

Discover IEMCA high-pressure systems designed for your sliding headstock lathe →

Integrating a high-pressure system with your sliding headstock lathe can make a significant difference in terms of tool life, finished part quality, machining speed and, more generally, overall productivity.

However, choosing a high-pressure system cannot be based solely on pressure and flow rate: it is essential to also consider flexibility in configuring outlet pressures, energy efficiency, activation times, maintenance frequency and complexity, footprint, and the degree of layout flexibility. Only a complete analysis makes it possible to identify the most suitable and truly advantageous solution for production.

Contact IEMCA to identify the high-pressure system best suited to your production needs and take your workshop to the next level of efficiency.