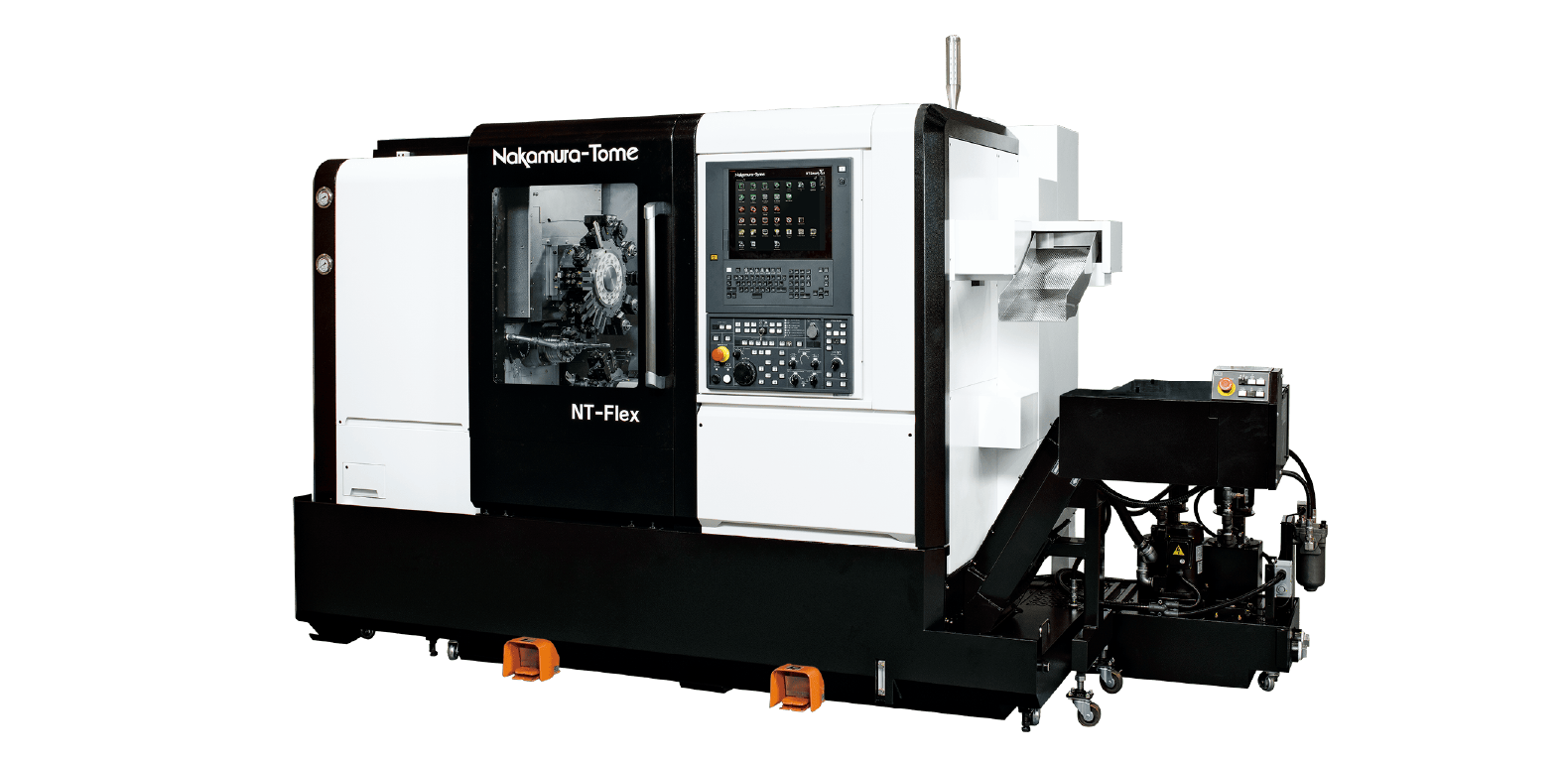

The philosophy behind the Nakamura-Tome NT-Flex lathe – and its NT-Flex+ variant – is captured in the concept “Compact Meets Flexibility”: the perfect union of operational flexibility and a compact footprint, designed to meet the fast-evolving needs of modern production departments.

This is a high-precision multitasking machine tool engineered for machining complex components. Equipped with two spindles and two turrets, it delivers extraordinary productivity despite its compact size. The compact structure can host 24-station turrets both on the upper and lower positions: when using quadruple toolholders, it is possible to install up to 96 tools, enabling the completion of all machining processes – turning, milling, threading – in a single setup.

The Nakamura-Tome NT-Flex is also equipped with the exclusive “ChronoCut” software function, specifically developed to reduce idle times during the machining cycle without compromising accuracy or altering cutting conditions.

Go to the full NT-Flex product page →

If you're considering adding a Nakamura-Tome NT-Flex to your machine fleet, it is essential to pay attention to the choice of peripherals. To enable the lathe to reach its full potential, every component of the production ecosystem must deliver maximum quality, reliability, and productivity. Among these, the bar feeder plays an absolutely crucial role.

The integration between NT-Flex and the bar feeder directly affects the overall performance of the application. Here are the essential characteristics a bar feeder must have to effectively support Nakamura-Tome NT-Flex:

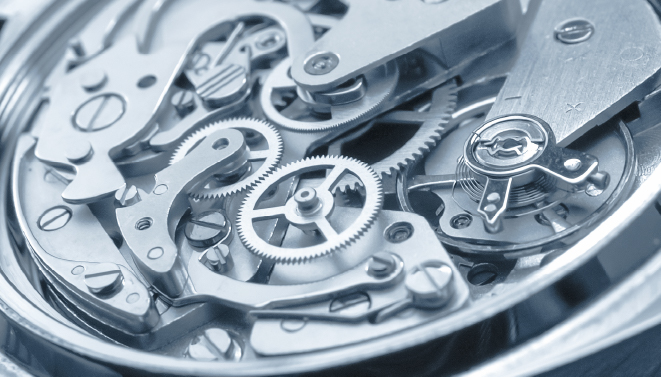

The bar feeder must ensure maximum stability and precision, even with shaped profiles and high rotation speeds, to achieve optimal finished part quality.

Nakamura-Tome NT-Flex is designed to ensure continuous operation: the bar feeder must do the same. Fast bar changes, minimal idle times, and autonomy suited to high production rates are essential requirements.

The bar feeder must be perfectly aligned with NT-Flex to support it effectively in any machining scenario without compromising performance.

The autonomy of the bar feeder is a strategic factor to ensure production continuity and increase the overall efficiency of the application.

The Iemca BOSS bar feeder guarantees full compatibility with Nakamura-Tome NT-Flex in all its configurations. Its technology directly and effectively meets the specific needs of this advanced machine.

Iemca BOSS technical features →

The pairing of Nakamura-Tome NT-Flex and Iemca BOSS bar feeder perfectly meets the quality standards demanded by the most discerning markets: absolute precision, operational continuity, long-term reliability, and top-level productivity.

Nakamura-Tome NT-Flex is engineered for extremely high production performance. The bar feeder must be up to the task: Iemca BOSS ensures precision, stability, and reliability, confirming itself as the ideal solution to fully leverage the potential of the machine tool.

Every production environment has specific needs. A detailed analysis of your requirements allows us to define the optimal configuration of Iemca BOSS to maximize the efficiency of your application with Nakamura-Tome NT-Flex.

Contact our Bucci Industries Japan branch for personalized consulting and discover how to optimize your investment in Nakamura-Tome NT-Flex technology with the most suitable Iemca BOSS bar feeder for your production needs.