In turning with fixed headstock lathes, knowing how to manage and minimize vibration generation is essential to ensure maximum precision and quality of machining.

Vibrations, caused by the dynamic interaction between spindle, tool, and workpiece, can compromise surface finish, reduce tool life, damage the spindle, and negatively impact production efficiency.

To keep vibrations under control on fixed headstock lathes—especially when working with long bars of any diameter—it is crucial to pay attention to every detail of the machine ecosystem, starting from the peripherals.

In particular, it is necessary to carefully evaluate the characteristics of the bar feeder chosen to support the lathe. It is not enough to consider only the bar guiding system: the installation distance from the spindle and the structure of the feeder itself directly affect its ability to contain vibrations and guarantee top-quality machining.

1. The bar guiding system

The bar feeder’s guiding system is a key element for ensuring stability and precision on fixed headstock lathes.

An effective guiding system adapts to the diameter of the bar being machined, accompanying it smoothly and continuously to minimize oscillations and misalignments.

It does more than just contain the bar: it actively absorbs vibrations generated during machining. An optimal guiding system includes high damping capacity materials and a channel adjustable according to the bar and pusher diameter.

When evaluating a bar feeder for a fixed headstock lathe, make sure it includes a modern guiding system, designed for smooth, precise, and vibration-controlling feeding throughout the entire work cycle.

Learn more about the role of the guiding system in reducing vibrations on fixed headstock lathes →

2. The installation distance between bar feeder and lathe

The position of the bar feeder relative to the lathe has a direct impact on vibration control in fixed headstock applications. If the distance is excessive, the free length of the bar increases, making it more prone to bending, oscillations, and vibrations.

To achieve maximum stability and precision, it is essential that the bar feeder be positioned at the correct distance from the machine tool. A well-calibrated installation helps minimize vibrations, even during the most demanding machining operations.

Ensure that the installation layout is carefully defined and that the bar feeder is properly positioned relative to the lathe.

Learn more about the importance of proper installation distance between bar feeder and lathe →

3. The structure of the bar feeder

When working with fixed headstock lathes, the structural rigidity of the bar feeder is crucial to control vibration generation and transmission.

The bar feeder’s structure must ensure controlled dynamic behavior, robustness, and stability, in order to protect the installation’s precision, efficiency, and long-term reliability.

A robust structure includes elements such as a reinforced central body, a solid base, and a stable anchoring to the ground.

Carefully assess the bar feeder’s structure at the selection stage to ensure robustness, stability, and rigidity.

Learn how the bar feeder’s structure impacts machining quality →

How to choose the bar feeder to reduce vibrations on fixed headstock lathes

Minimizing vibrations in fixed headstock lathes requires an optimized configuration of the entire application. In particular, when selecting the bar feeder to support the lathe, it is essential to consider these three key aspects:

- The bar guiding system, which must be flexible, damped, and designed to best accompany the bar through every stage of the cycle.

- The installation distance from the lathe, to be precisely calibrated to limit oscillations and bending between bar feeder and spindle.

- The structure of the bar feeder, which must ensure robustness, stability, and the ability to effectively dampen vibrations.

Investing in a bar feeder designed with these elements in mind means minimizing the impact of vibrations in fixed headstock machining, ensuring precision and quality, and protecting the durability and efficiency of the entire installation.

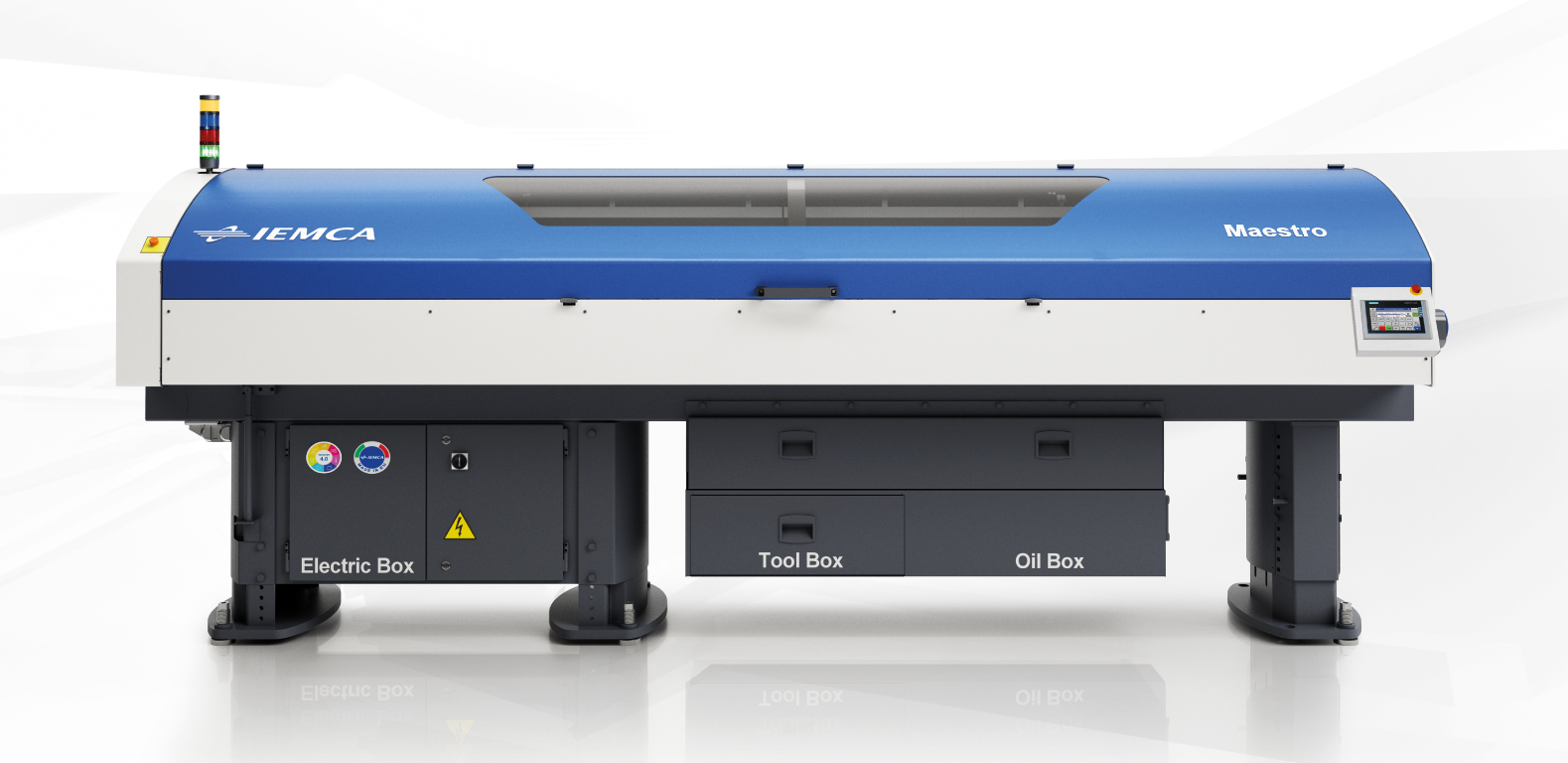

Are you looking for a bar feeder for a fixed headstock lathe?

The bar feeders of the IEMCA MAESTRO range offer:

- Patented ABACOS system: self-adjusting damping material bushings that adapt to the diameter of the bar and pusher.

- Reduced installation distance: thanks to the use of short pushers, the bar feeder can be positioned closer to the lathe than traditional solutions allow.

- Robust structure: extra-rigid central beam and reinforced lower frame for maximum robustness and stability.

Explore the technical sheet or contact us today for personalized consultation.