In machining with fixed headstock lathes, the generation of vibrations cannot be avoided: what matters is knowing how to act on the installation to manage and minimise them.

This is in fact a natural phenomenon, linked to the dynamics of the interaction between the spindle system, the cutting tool, and the workpiece. If not properly controlled, vibrations can compromise the surface finish quality, reduce tool life, damage the spindle, and more generally have a negative impact on overall productivity.

To correctly manage vibrations, it is essential to understand the variables that influence their generation. Among these, one often underestimated element is the bar feeder chosen to work alongside the fixed headstock lathe – and in particular the features of its bar guiding system.

Why the Bar Guiding System is Crucial in Fixed Headstock Machining

On fixed headstock lathes, long bars are often machined: even the slightest instability can generate significant vibrations. For this reason, the bar feeder guiding system plays a key role in ensuring bar stability and reducing vibrations throughout the machining cycle.

An effective guiding system must be able to adapt as closely as possible to the bar diameter, smoothly accompanying it during rotation to minimise oscillations and misalignments.

An optimal guiding system does more than just contain the bar: every single detail must be designed to absorb and actively dampen vibrations, protecting the machine and preserving the final quality of the part. High damping-capacity materials and an adjustable guide channel according to the bar diameter contribute to improving the installation setup and its ability to manage vibrations.

ABACOS: the Flexible Guiding System for Fixed Headstock Lathes

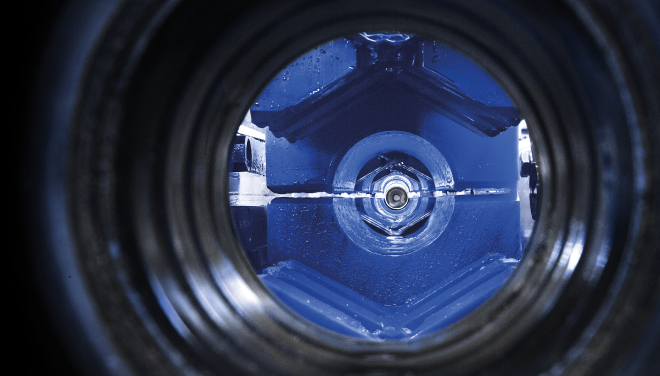

The bar feeders for fixed headstock lathes IEMCA MAESTRO are designed to ensure optimal bar guidance inside the spindle, even in the most complex and demanding applications. Special attention has been dedicated to developing a solution effective in vibration management.

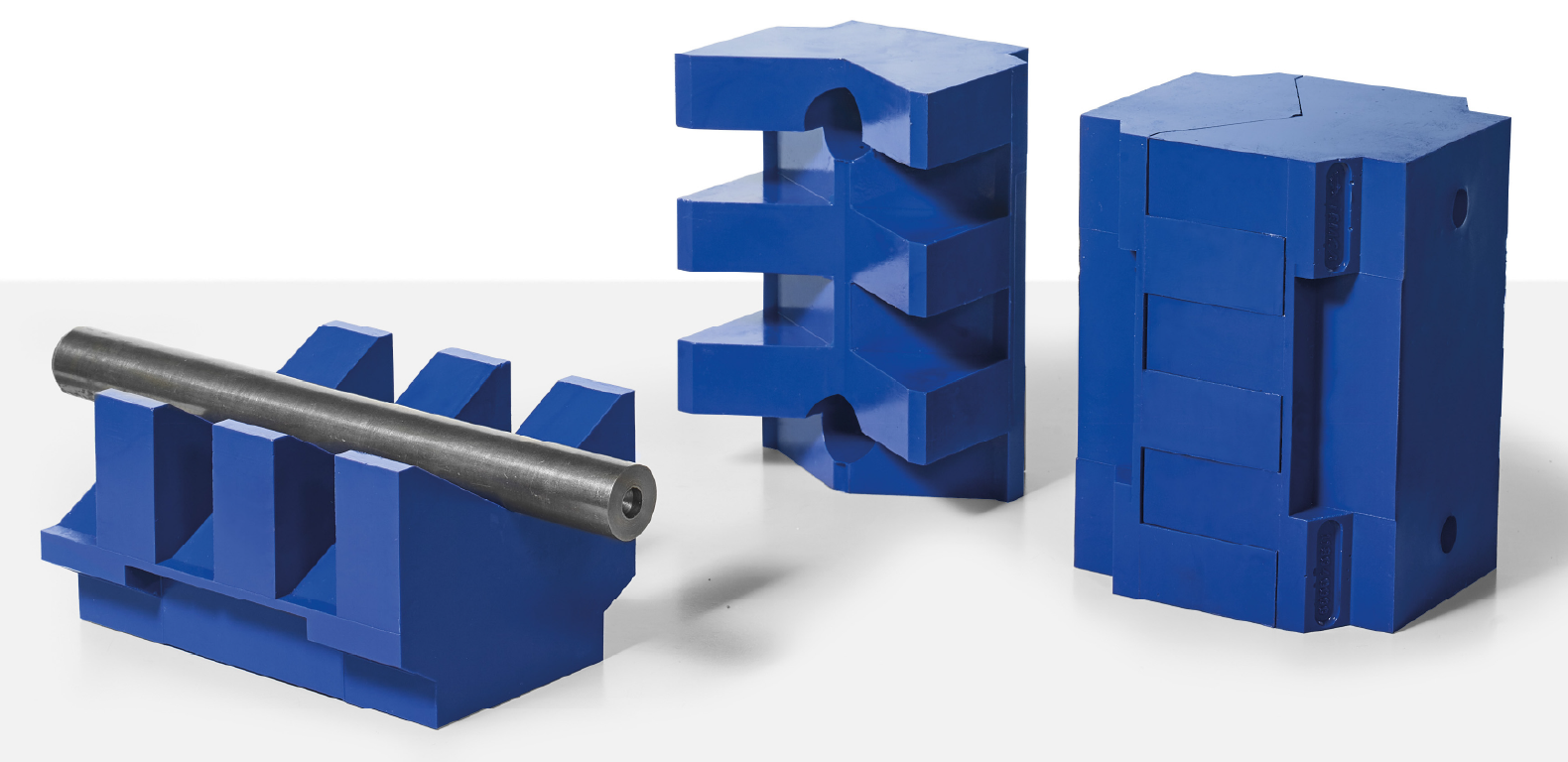

The MAESTRO range is equipped with the patented IEMCA ABACOS (Adaptive BAr COntrol System), which uses self-adjusting bushings that adapt to the diameter of the bar being machined.

- The self-adjusting bushings automatically adapt to the diameter, guiding the bar effectively throughout the machining cycle.

- Thanks to their innovative shape, the ABACOS system ensures 4 constant-length contact points with the bar (regardless of diameter), guaranteeing precise and effective support.

- The system is equipped with a lubrication circuit that reduces friction between bushings and bar, ensuring smoother rotation.

- The integrated pneumatic system actively absorbs vibrations generated during machining, minimising their impact on the installation.

- The bushings are made of a material specifically developed to dampen vibrations.

- The ABACOS system can also clamp the bar pusher, automatically adapting to its diameter: a potential disturbance is neutralised and maximum stability is ensured throughout the production cycle.

Fewer Vibrations, Higher Productivity: Benefits for Your Fixed Headstock Lathe

Thanks to the ABACOS system applied on MAESTRO bar feeders for fixed headstock lathes, vibrations generated during machining are kept under control, and productivity and precision of the application are increased.

Fewer vibrations mean better surface finish and part quality, less tool wear, greater reliability, and higher productivity of the entire installation.

Find out how MAESTRO can optimise your fixed headstock machining: contact our team for a dedicated consultation.